Our client, an award-winning biopharmaceutical contract services company, required a custom heat treatment system delivered within 16 weeks. BFC worked tirelessly to provide an innovative, high-quality solution within a very tight deadline. Our inherent team-based approach meant that we were able to collaborate with our client and work towards a common goal. Despite having very little buffer in the project schedule, we were able to deliver the system in time for the scheduled shutdown.

Deliver a custom designed heat treatment system

- Process constraints included:

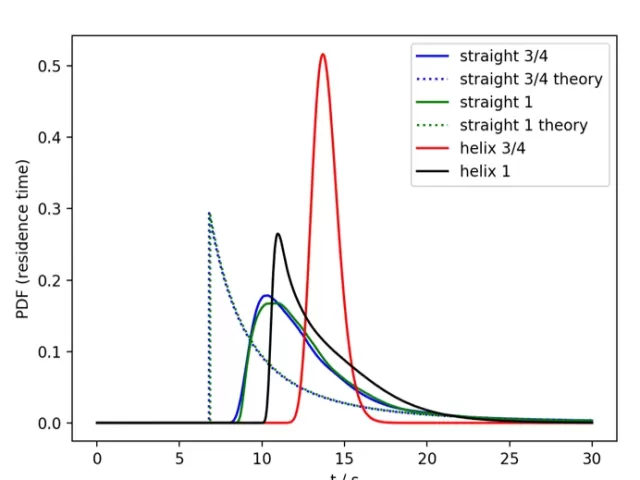

- Residence time 14 sec (exchangeable retention coils)

- Temperature control 77 °C to 83 °C +1°C

- Flow rate 5 to 10 L/min + 0.5L/min

- Interfacing with the existing steam system provided challenges that required software adjustments

- The system was ready for scheduled shutdown.

- The system performance met critical quality control points.

- The custom retention tube design provided an innovative solution for our client.