A global leader in healthcare requested the services of BFC to design and build 21 customized filtration skids in support of their capacity expansion. Our multidisciplinary team worked with our client’s best interests to deliver validated systems, packaged and ready for installation ahead of the completed building. We are proud of our flexibility as a company; and on this project we were able to adapt quickly to client-motivated design changes. The efficient FATs run by BFC, not only saved our client time, but also reaffirmed our commitment to delivering on our promises

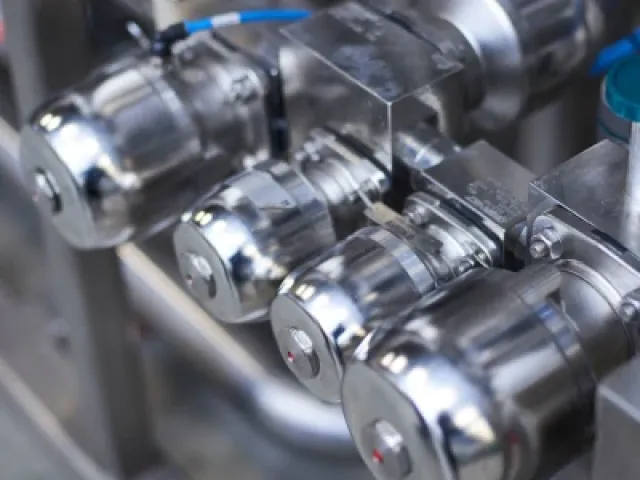

Supply custom filtration systems including process design, automation, fabrication, and qualification

- Process design changes while fabrication was underway

- Room size limitations required extensive 3D modeling efforts to accommodate the skids in the allocated space

- Integration with on - going site utility design changes

- Successfully designed systems to fit in a small footprint while still allowing sufficient access for cleaning and maintenance

- Factory Acceptance Tests (FAT) ran efficiently

- Equipment was ready for shipment prior to being required on site